Let's Weave . . . Bead Leno

As with the series "Let's Spin . . ." that I started with this post "Let's Spin . . . Coopworth", I'm starting a similar series on weaving. The purpose of this series is to bring you weave structures and techniques that may be new to you. There are certainly a lot of resources out there that explain and demonstrate these, but I have found that sometimes the many choices seem overwhelming. If you're like me, sometimes just deciding what to try next becomes the stumbling block. So my hope is that by providing you some information and an example of something I've actually woven, you might just say, "Hey, I can do that!".

I'll start this series with Bead Leno. Several of my misperceptions about Bead Leno were:

- Bead Leno involves adding beads to the weaving

- False - although I added beads to the fringe of my scarf, there are no beads actually woven into bead leno fabric.

- Leno is pronounced like Jay Leno

- False - Leno is pronounced 'lee-no'

Leno is considered a woven lace, sometimes referred to as a guaze lace. It is created by twisting the warp ends around each other and holding the twist with a weft shot. The crossed warp threads create holes that produce the lace effect. Despite being a very open structure, leno is quite stable and sturdy.

Originally, leno was formed using a pick-ip stick to twist warp threads, passing the shuttle through the area formed by the twist. Later, specialized heddles called doups (string loops) were used to twist the threads. Eventually someone had the idea of replacing doups with beads to form the twists, and this last method came to be called bead leno.

Leno can be still be achieved by any of these methods. Below is an example of leno I did on a rigid heddle loom using a pick up stick. You can see the twist of the warp threads with a pick (horizontal white thread) holding it in place.

If you want to give doup leno a try, here is a link to a You Tube video by Kelly Casanova on "How to Make a Heddle Rod" where she describes making string heddles (doups); her explanation starts at about 55 seconds into the video.

Now, back to bead leno. So, a 'bead' is used to twist the warp threads and create the leno effect. For my 'bead', I used 1/4" split rings (also known as charm rings or snap rings). Another suggestion would be plastic pony beads. A small crochet hook was helpful to thread the 'bead' (split ring) on the warp threads.

The outermost threads in each 4-thread group of warp ends are crossed under their adjacent ends and threaded through a 'bead' in front of the heddles but behind the reed.

Technical Alert - For a rising shed loom, the warp ends from shafts 1 and 4 are threaded thorough a bead below the warp ends on shafts 2 and 3. Each 4-thread group is threaded through the same dent in the reed. When either of the shafts with a warp end that runs through the bead is raised (shafts 1 or 4), it pulls the other warp end under the two center nonbeaded ends, twisting the warp group. The weft pick is then inserted to hold the twist in place.

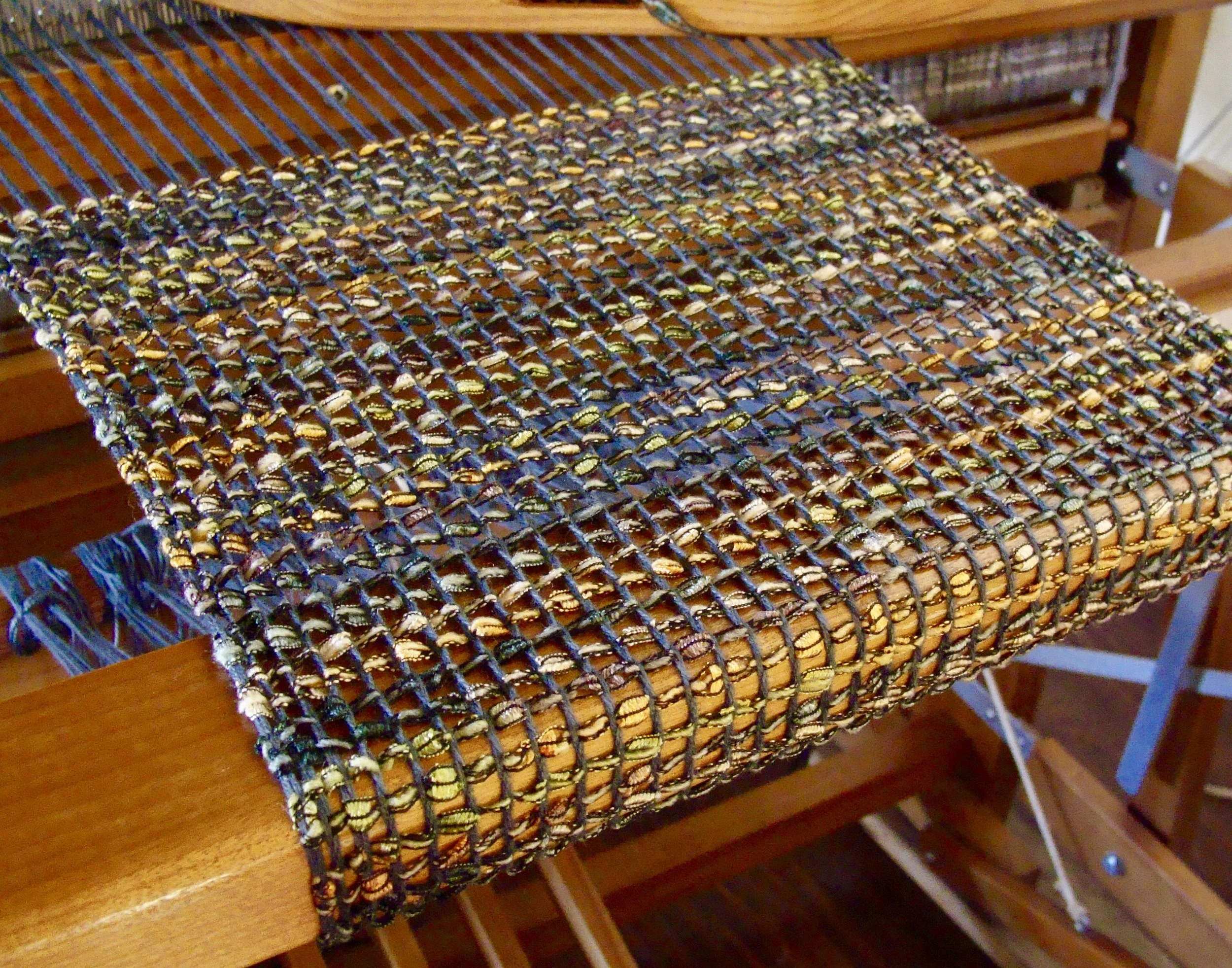

For my bead leno project, I wove a scarf based on an article by Marvelyn Albert in the September/October 2006 edition of Handwoven magazine (p. 48-51). For the warp yarn I used Interlacements Soya (50% silk/50% soy silk). For the weft, I chose a "trellis" novelty yarn, Universal Yarn Felicity (72% nylon, 14% acrylic, 14% wool).

To finish the scarf, I twisted the fringe, threading a 6/0 glass seed bead (this time a real bead :-) onto each group of 4 threads.

Weaving Considerations with Bead Leno:

- The warp yarn must be strong enough to withstand the twisting and crossing of the threads.

- The use of the bead will reduce the size of the shed. I found I needed to advance the warp often while weaving. In my study, some recommended using the last 4 shafts on an 8 shaft loom to get a better shed. However, I really had no shed issues on my 4 shaft loom.

- Sometimes the bead (split ring) would come through the reed when I advanced the warp. But it was easily pushed back through with a hair pick.

- Uneven draw-in can be an issue with leno since the lace areas often end up being narrower than the background areas. The leno areas have far fewer picks per inch than say plain-weave areas. Since my scarf was all bead leno, I did not have any uneven draw in issues. I was a little concerned while weaving, that there was more general draw in than usual. However, once off the loom, I noted only a 2 2/3" actual width loss (12 2/3" width in reed versus 10" width off loom after wet finishing).

The finished scarf is 10" x 58" + 5" fringe on either end. The lacy bead leno weave structure makes a very light and airy scarf; perfect for when the weather is hot and humid in South Carolina.

I hope this inspires you to try bead leno. Here are some variations you might consider:

- Intermix with plain weave as a background for the leno.

- Add leno as a decorative element or border on your fabric

- Play with color combinations in the warp to create interesting patterns

Mary Meigs Atwater wrote almost a century ago in her book "The Shuttle-Craft Book of American Hand-Weaving":

The leno weaves, though not the simplest weaves in the hand-weaver's repertory, present no great difficulties, as may be seen. For many useful purposes they are the best possible weaves and no with a suitable loom need hesitate to try them.

Good enough for me!