Let's Spin . . . Coopworth

Today is the first installment of a recurring feature that I'm calling "Let's Spin . . . " There is such a myriad of fibers that can be handspun - wool, mohair, angora, cotton, flax, bamboo, polyester, silk, alpaca, and so much more! As I work my way through spinning these varied fibers, I plan to share what I learn both from my study, as well as my experience with the fiber. I hope you enjoy and find inspiration!

Having a basic familiarity with a few terms will help to understand the fiber's characteristics and ultimately its end use. Here are a few terms to get started with:

Staple length - the average length of fibers from a particular source; in animal fiber, a staple is sometimes referred to as a lock. In general, longer fibers create stronger and shinier yarns providing fabrics which wear better. Shorter fibers tend to be softer, but may pill more. (Tip-when measuring the staple length, don't straighten out the crimp).

Fiber Diameter - how thick the fibers are; expressed in microns, or one millionth of a meter. The lower the micron count, the finer and softer the fiber. The larger the fiber diameter the more durable and less soft.

Crimp - kink or wave in the wool that affects the behavior of the finished yarn or fabric, such as elasticity (stretch), resiliency (spring back), loft (insulation).

Luster - natural shine of the fiber. In general, the longer the fiber, the more luster.

Handle - the feel of the fiber; descriptors like soft, harsh, prickly. Handle directly relates to the thickness of the fiber. That's why finer fibers, such as angora and cashmere, have a soft feel. A general recommendation is that fibers for use close to the skin have a maximum diameter of 20 to 22 microns, whereas fibers for heavy duty outdoor wear have a maximum diameter of 30 to 32 microns.

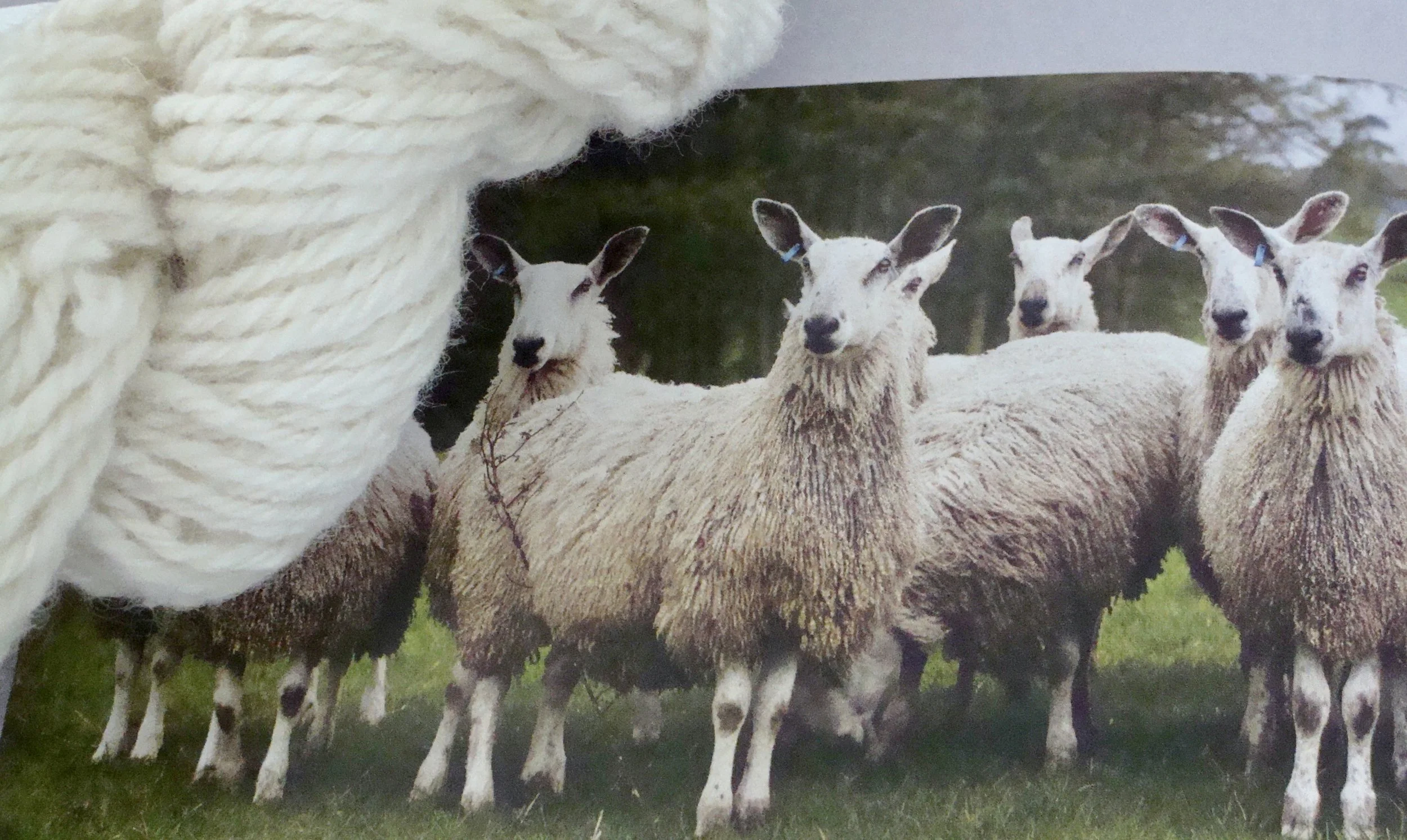

Today's feature breed is Coopworth, an Australasian sheep breed. The Coopworth breed was developed by Professor Ian Coop in New Zealand in the 1950s by crossing Border Leicester rams with Romney ewes.

photo American Coopworth Registry

According to the American Coopworth Registry, "Coopworth sheep are a medium sized, dual purpose, longwool breed with an alert but quiet disposition". Both white and natural colored (grays more common than browns) Coopworths are accepted for registration. Coopworth can have a variability in their fibers, however, in general, they're described as long staple, lustrous, with a soft handle, and a well-defined crimp.

The typical staple length is 5 to 8 inches and a fiber diameter of 30 to 39 microns. Coopworth tends to be better suited for outerwear (hats, mittens, scarves) and utility textiles (throws) rather than next to the skin garments.

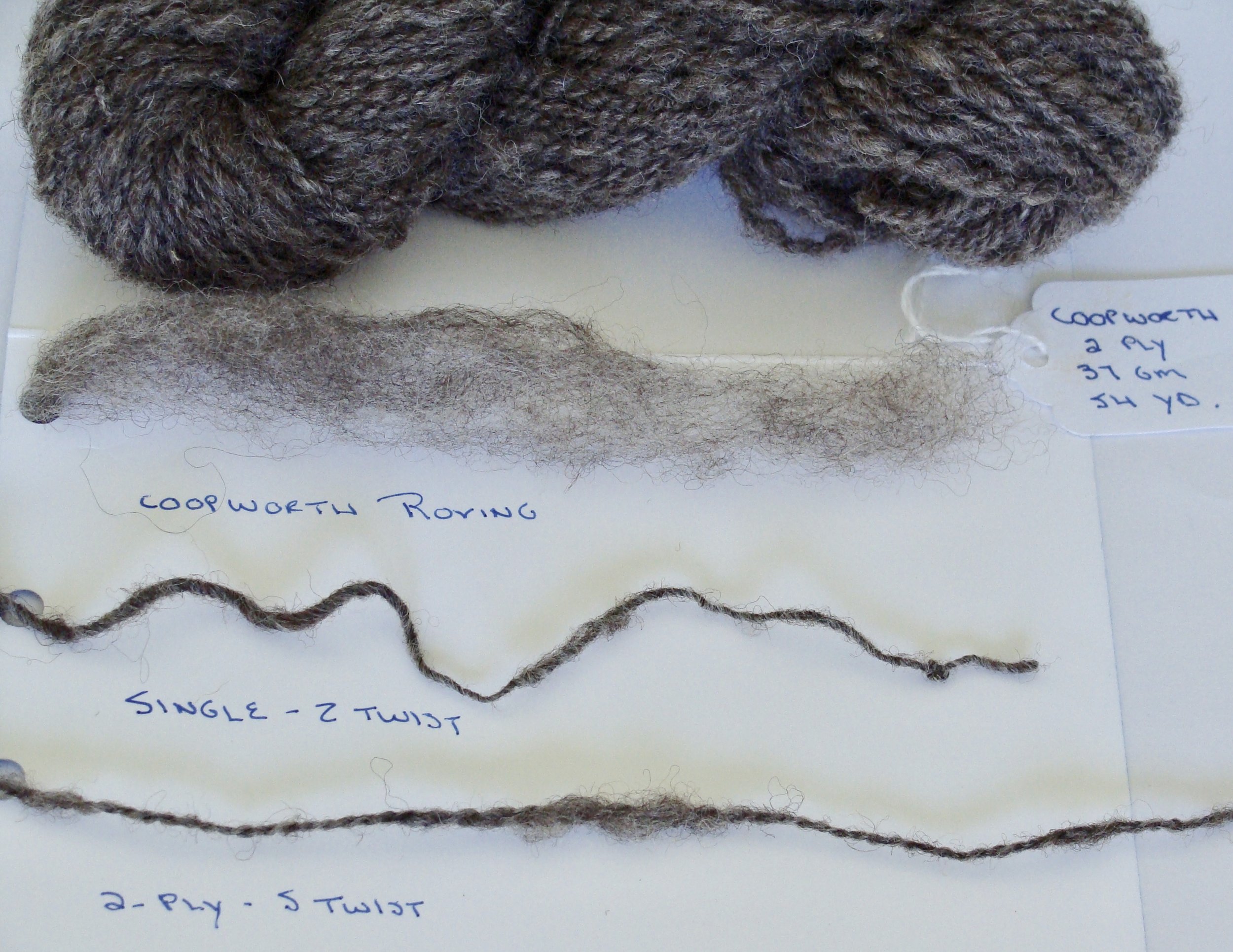

Coopworth fleece can be spun from the lock or combed. Even though combed fibers are usually sold as top, combed Coopworth looks and acts more like roving. I am spinning Coopworth fiber from Louet in the medium colorway. I have Coopworth roving for sale in my shop here.

Coopworth roving I'm spinning

In exploring how others spin Coopworth, I found quite a few that recommended spinning on a spindle rather than a wheel. Their observation was that Coopworth had a tendency to be overspun on a wheel, while spindle spinning kept the yarn light and fluffy . I actually purchased my Coopworth fiber as part of a spindle kit and I initially started to spin with this. However, my spindle attempt was pretty sad; I've definitely not befriended the spindle . . . yet! In all fairness to the spindle, my spindling adventure was 6 months ago and I had yet to even trial a spinning wheel. Although some spinners start on a spindle, I was not one of those who benefitted from this introduction to spinning.

Instead, I spun my Coopworth roving on my Louet S17 wheel. First, I took my so called "yarn" off the spindle and respun what I could salvage; probably not the most technically correct thing to do, but hey, I am exploring . . . and I'm German remember! Initially, I used the medium ratio (1:7.5) and with a short draw technique. This is basically how I've been spinning other wool fibers, which to date have mainly consisted of Merino. Unlike Merino, the Coopworth was not soft when spun by this method. The result was a yarn that was fairly thin and on the overtwisted side. On the bobbin it seemed to be kind of . . . well . . . coarse . . . reminding me of twine; definitely not giving justice to the fluffiness of the Coopworth fiber. So, I changed to the slowest ratio (1:5.5) and consciously began to treadle slower; holding the fiber lightly to keep a nice, softly spun yarn. This produced a loftier, softer yarn that I think fits more with the Coopworth fiber!

Coopworth wool handspun single

You can see in the photo above, the single appears somewhat overtwisted. I had to weight it on either end to get this photo. So, when I plied the yarn, I decided to go back to the 1:7.5 ratio with a S-twist hoping this would calm the 'twist beast' a bit. I think it worked. Below is a photo of the 2-ply before finishing.

Coopworth wool handspun 2-ply unfinished

To finish (or set) the yarn, I soaked it in hot water with a drop or two of Woolite for about 5 minutes, gently squeezed out the water, and hung to dry unweighted.

Coopworth wool handspun 2-ply after finishing

A characteristic of this Coopworth roving was that it had a fair amount of neps. I chose to not process the fiber any further, and I purposely spun it to have texture with thin and thick spots and slubs. My goal was for an organic, rustic look and feel to the yarn. I'm pleased with the result and think I succeeded in achieving my intention.

Nep (or Noil) - a tangled knot of short broken fibers.

The end result: I'd call it a worsted weight yarn, roughly 9-10 wraps/inch (wpi); 54 yards; 37 grams. I like the "tweediness" of the yarn with the variation in shades of gray. The yarn is fairly lofty. I wouldn't call it soft, but it's not terribly coarse either. If I spun more, I could see mittens or a hat as a nice use for this yarn.

I'll end this post with a recommendation. Deborah Robson is an absolute guru of fiber information. I highly recommend several of her resources:

The Fleece and Fiber Sourcebook - More than 200 Fibers from Animal to Spun Yarn

Know Your Wool (a FREE class on Craftsy)

Also, a YouTube video where she talks about pilling (why and what you can do)